Stainless Steel Welding Mesh Material Testing And Technology, Characteristics

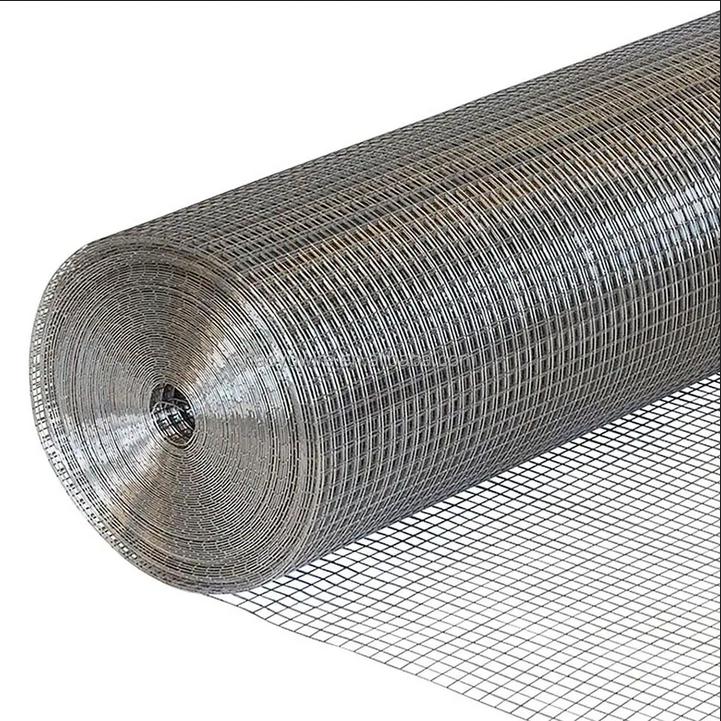

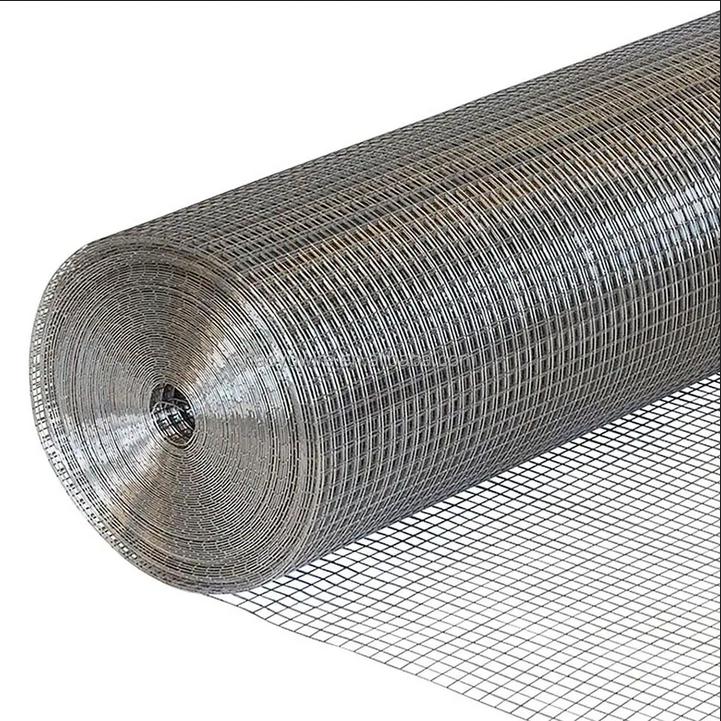

Stainless steel welding mesh is made of stainless steel wire row welding, the mesh surface is smooth, uniform mesh, solid solder joint, local machining performance is good, stable, anti-corrosion, corrosion resistance.

Stainless steel welding mesh: stainless steel welding mesh usually uses 201,202,304,304L, 316,316 L stainless steel wire as the material, through precision automation mechanical technology processing, mesh surface flat, strong structure, strong integrity, even if the local cutting or local pressure will not occur loosening phenomenon. Stainless steel wire mesh is one of stainless steel wire mesh products. Stainless steel welding mesh features: has strong anti-corrosion and anti-oxidation properties, solid solder joint, strong tension, bright surface. Stainless steel welding net uses: stainless steel welding net is mainly used in mining, petroleum, chemical industry, food, medicine, machinery manufacturing and other industries of machinery and equipment protection.

Inspection of material

Stainless steel welding surface can be understood as non-rust steel, this understanding is too simple, stainless steel material is not absolutely not rust, but the first under certain conditions, corrosion resistance and rust resistance is strong. Anyway, when we purchase stainless steel products, in addition to pay attention to the products of the factory inspection certificate or certificate of quality, to pay attention to the reputation of the business, rather than just blindly covet cheap.

Process and Features

Using stainless steel wire welding, the process effect is very good, not only the surface bright, smooth, life and anti-corrosion ability can be fully reflected. Welding firm, net surface smooth, acid and alkali resistant, beautiful, corrosion resistance is very strong